How To Fix Discolored Concrete (Eco-Friendly)

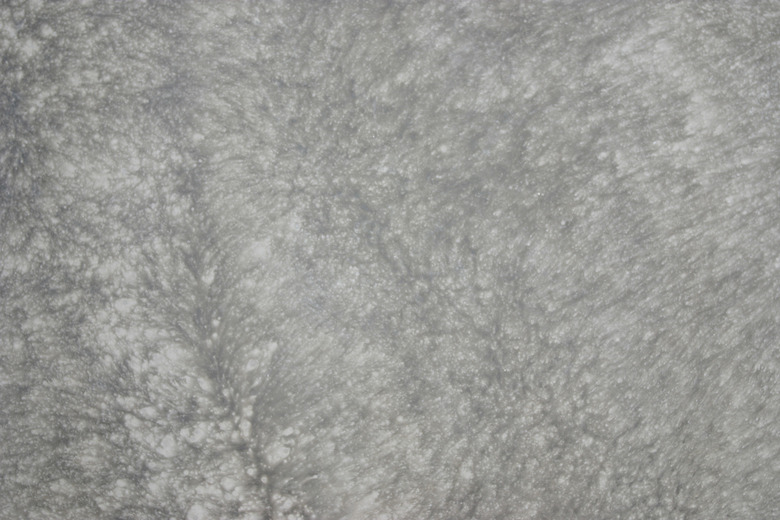

You may have noticed dark spots or discoloration in your outdoor concrete. This is known as mottled concrete or pinto concrete. Many things can cause this to happen such as the concrete to water ratio, hard troweled surfaces, improper/inadequate curing, maybe even calcium chloride additives. There is a simple, eco-friendly solution.

Step 1

Prepare the surface of the discolored areas by hosing off the area, while scrubbing with your outdoor broom.

Step 2

Pour the vinegar directly on the discolored area. Do this in the morning and let it sit for approximately 30 minutes. Rinse thoroughly with your hose. Re-apply the vinegar as needed. The vinegar and the heat open the pores of the concrete, allowing any trapped moisture to escape and giving you access to the deeper parts of the stain.

- You may have noticed dark spots or discoloration in your outdoor concrete.

- Prepare the surface of the discolored areas by hosing off the area, while scrubbing with your outdoor broom.

Step 3

Before the day begins to cool, scrub the area with your outdoor broom then hose it off. The stain should be gone, it may even have faded while the vinegar was sitting.

Lay Concrete

Laying concrete is one of the simplest things you can do to spruce up your curb appeal or backyard. Once you've read up on how to lay concrete, it's a relatively easy project that can be done in an afternoon. Determine the slope of the yard and adjust the perimeter of the slab accordingly. Use a level to ensure boards are straight. For example, if you were laying a 12-by-16-foot concrete patio off of a back door, your form would consist of two 12-foot 2-by-4s and one 16-foot 2-by-4. The amount needed depends on the size and scope of your project. This step also helps support the concrete and prevent it from cracking, especially if you're layering on top of existing concrete. You'll probably need a wheelbarrow or other large trough for this. Before pouring the concrete, wet the ground thoroughly with a garden hose, especially if you're working with bare dirt beneath your rebar or crushed stone layer. This prevents the ground from absorbing all of the concrete's moisture, which encourages the slab to dry evenly. If you're expecting inclement weather before the concrete has properly dried, cover it with a tarp to protect it.

- Before the day begins to cool, scrub the area with your outdoor broom then hose it off.

- Before pouring the concrete, wet the ground thoroughly with a garden hose, especially if you're working with bare dirt beneath your rebar or crushed stone layer.

Things Needed

- White vinegar

- Garden hose

- Outdoor Broom

Tip

Do this during the summer For best results, do this in direct sunlight Tougher stains or deeper discolorations may require this to be done more than once.