Can I Use A Reducer Gearbox As An Increaser?

Reducer gearboxes are the most common type used in industry, transportation and appliances. This is due to the vast majority of gearbox applications requiring reduction of a motor's shaft speed while increasing its torque. There are specialized applications that require just the opposite, however–an increase in shaft speed with a proportionately lower torque. While most increaser gearboxes are specially designed to be increasers, there are a few reducer gearboxes that may be turned around to increase speed under very limited conditions.

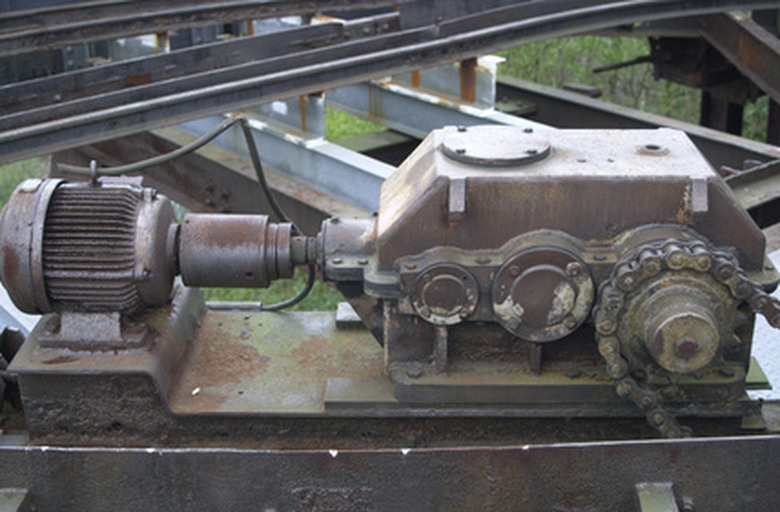

Matching Inputs and Outputs

Using a reducer gearbox as an increaser is a matter of turning a viable reducer around 180-degrees and putting a rotational input into the reducer's output, in order to receive a higher speed output on the reducer's input shaft. Success in doing this starts with selecting the right kind and size of reducer gearbox for the specific increaser application. The trick is in picking a reducer where its input and output specifications can be closely matched to the increaser's output and input specifications, respectively.

- Reducer gearboxes are the most common type used in industry, transportation and appliances.

- There are specialized applications that require just the opposite, however–an increase in shaft speed with a proportionately lower torque.

Picking a Type

Select an increaser type and ratio that is usable for your increaser application. These are spur and helical single stage, bevel and planetary types where the increasing ratio will be a maximum of about 1:4. Therefore, a possible single-stage reducer, in which a single small input gear drives a single large output gear, would have a maximum reduction ratio of about 4:1.

Calculating Torque

Use the general formulas for torque, revolutions-per-minute (rpm) and horsepower for electric motor applications to determine the size, ratio and robustness of the reduction gearbox you will use as an increaser. These are: HP = rpm x torque / 5252 and torque = HP x 5252 / rpm. Reducer ratio = input rpm / output rpm.

Existing Reducer Example

You already have a reducer with a 3:1 ratio that is designed to be used with 2-horsepower motors turning at a maximum of 3450-rpm with 3 foot-pounds of torque applied to the input. This yields 9 foot-pounds torque and 1150-rpm on the output. Using this reducer as an increaser would limit you to applications with inputs that turn at 1150-rpm and 9 foot-pounds of torque and outputs that turn at 3450-rpm and 3 foot-pounds of torque. (Horsepower remains a constant, since rpm and torque are inversely proportional in a gearbox).

- Select an increaser type and ratio that is usable for your increaser application.

- You already have a reducer with a 3:1 ratio that is designed to be used with 2-horsepower motors turning at a maximum of 3450-rpm with 3 foot-pounds of torque applied to the input.

New Application Example

If you need to obtain a rotational output speed of 6000-rpm and output torque of 10 foot-pounds, with a 1500-rpm motor, you would need a 4:1 reducer gearbox to provide a 1:4 increaser ratio that can handle an 11-1/2 horsepower motor with at least 40 foot-pounds of torque.

Practical Application

If you want to turn a high-speed leaf blower impeller normally designed for 9000-rpm motors with a 6-horsepower lawn mower engine turning at 3000-rpm, you will need a 3:1 ratio increaser with at least a 6-horsepower rating or a torque rating of at least 10.5 foot-pounds. You will need to securely mount the gearbox on a frame with the engine shaft coupled directly to the output shaft of the 3:1 reducer. The impeller will have to be mounted on the gearbox's input shaft, with the impeller housing securely attached to the input shaft bearing frame. This will allow the engine's horsepower to be constant as it is stepped up in speed to drive the impeller at a proportionately lower torque; the result will be an extremely powerful blower.